Mechanical Grout Packer

A mechanical grout packer, also known as a mechanical injection packer or mechanical grout plug, is a specialized tool used in construction and civil engineering projects for injecting grout or other materials into cracks, joints, or voids within structures. It is designed to create a tight and durable seal to prevent the leakage of fluids or to provide structural reinforcement.

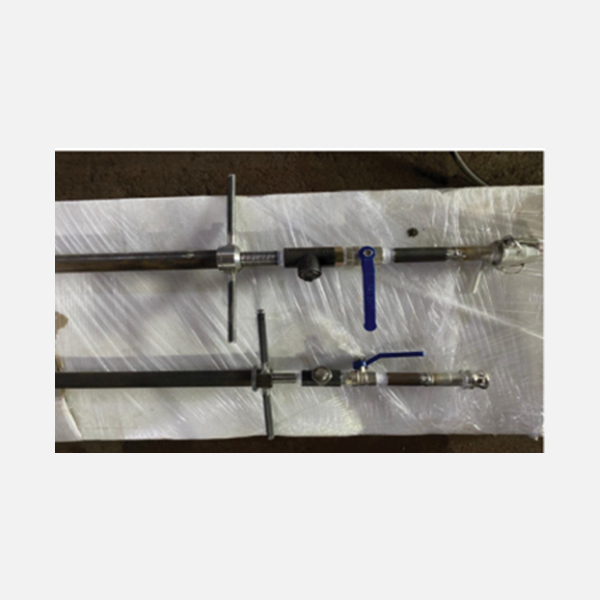

The mechanical grout packer typically consists of the following components: Packer Body: The packer body is the main housing of the mechanical grout packer. It is typically made of durable materials such as steel or high-strength plastic. The packer body is designed to withstand high pressures and provide a secure attachment to the structure being grouted.

Grout Injection Port: The grout injection port is a threaded opening on the packer body where grout or other materials are injected into the structure. It is connected to a grout pump or injection system to deliver the grout under pressure.

Valve Mechanism: The mechanical grout packer incorporates a valve mechanism that controls the flow of grout. The valve is typically actuated by rotating or tightening the packer body, allowing the grout to be injected into the targeted area. The valve mechanism helps to create a seal and prevent the backflow of grout or other fluids.

Sealing Element: The sealing element, often made of rubber or other elastomeric materials, is located at the tip of the mechanical grout packer. It forms a tight seal against the structure when the packer is tightened, preventing grout from escaping and ensuring efficient injection.

Attachment Mechanism: The mechanical grout packer is designed to be securely attached to the structure being grouted. It may incorporate various attachment mechanisms, such as threads, expansion mechanisms, or inflatable bladders, to provide a reliable connection and prevent movement during grout injection.

Mechanical grout packers are widely used in applications such as concrete repairs, waterproofing, soil stabilization, and structural strengthening. They allow precise and controlled injection of grout, ensuring effective sealing and reinforcement of the targeted areas. The packers are available in various sizes and designs to accommodate different project requirements and structures.

Proper installation and selection of the mechanical grout packer, along with appropriate grout materials, are essential to ensure successful and durable grouting results. Regular inspection and maintenance of the packers are also important to maintain their performance and prevent leaks or blockages during grout injection.